- An ISO 9001:2015, 14001:2015 & 45001:2018 Company

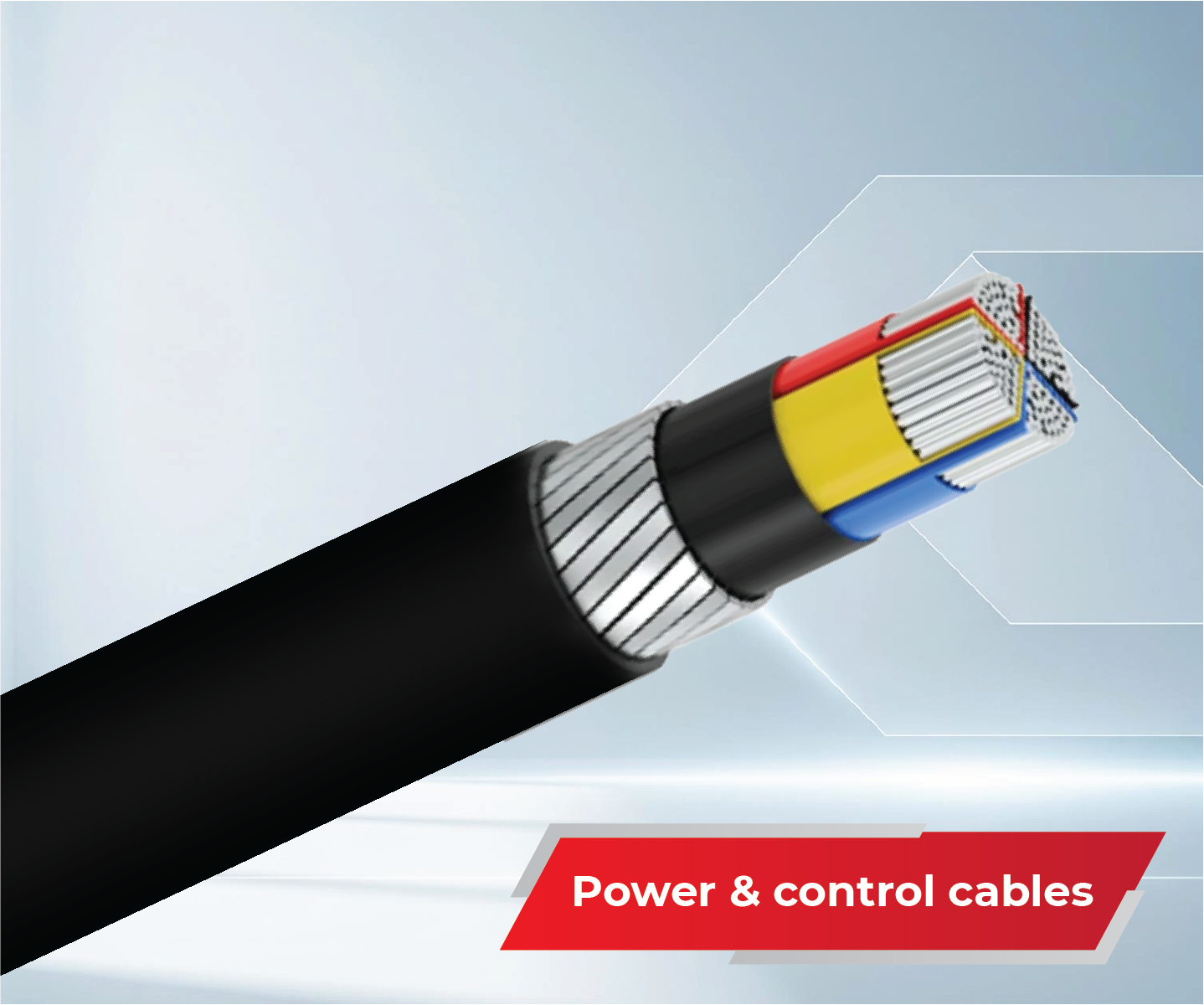

Power and control cables

Applicable Standards & Certifications :-

IS:694 – PVC Insulated Cables

IS:7098 (Part I) – XLPE Insulated Cables

IS:1554 (Part I) – Control & Power Cable Type Tests

BIS Licence No. CM/L-8780904 – PVC Aluminium/Copper Wires & Cables

Description :- PVC insulated cables, both armoured and unarmoured, are widely used in electrical wiring and power distribution. PVC (polyvinyl chloride) provides insulation, protecting against electric shock and fire, while also offering resistance to abrasion, chemicals, and moisture. Armoured cables have an additional layer of metallic protection, making them suitable for harsh environments and direct burial, whereas unarmoured cables are typically used in protected locations.

Product Details :-

- Product Range :-

- PVC insulated:Single core up to 1000 Sqmm. Multicore up to 400 Sqmm.

- XLPE insulated: Single core up to 630 Sqmm. Multicore up to 400 Sqmm

- Applications :-

- PVC insulated cables are widely used in domestic, commercial, industrial, and infrastructure applications for safe and reliable power distribution, control wiring, and lighting due to their durability, flexibility, and cost-effectiveness..

Features :-

- Good Insulation Resistance – Ensures safety and prevents leakage current

- Flame Retardant (FR) – PVC compounds can be made flame-resistant

- Wide Operating Temperature Range – Typically −15°C to +70°C (special PVC up to +105°C)

- Weatherproof & UV Resistant (special grades) – Suitable for outdoor use.

Technical details :-

- Rated Voltage: Commonly 300/500V, 450/750V, 1.1kV (depending on application).

- Conductor Material: Copper or aluminium, solid or stranded

- Insulation Material: Polyvinyl Chloride (PVC), available in FR (Flame Retardant), HR (Heat Resistant), FRLS (Flame Retardant Low Smoke), or Zero Halogen variants.

- Operating Temperature Range: −15°C to +70°C (standard), up to +85°C/+105°C for heat-resistant

Related Products

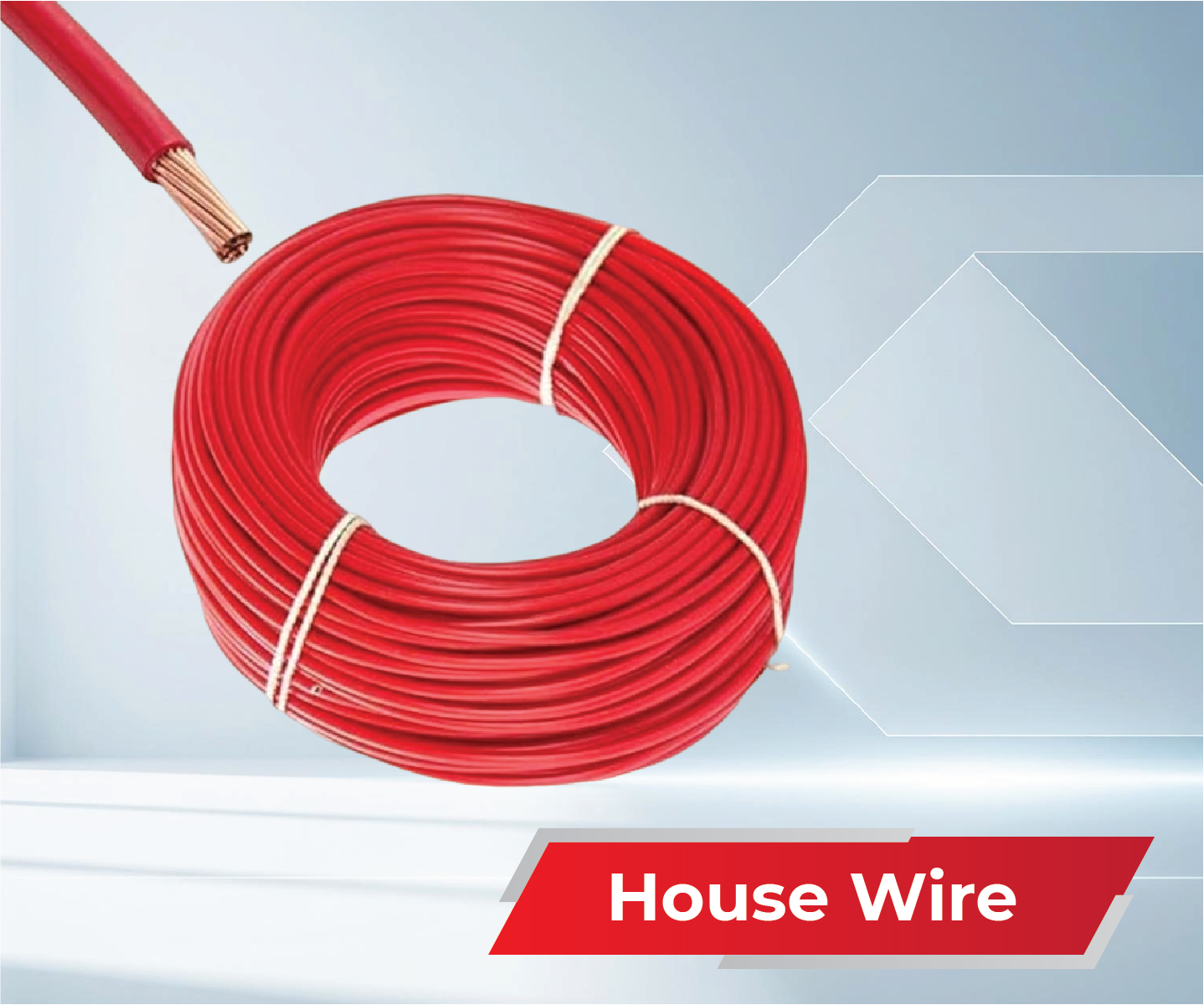

Home Reliable PVC House Wires for Safe Homes Description :- Durable, flexible, and cost-effective wiring solutions for domestic use.Made with high-quality PVC

Home High-Tension XLPE Power Cables — 11kV & 33kV Description :- Reliable transmission up to 33,000 volts. Built to endure high mechanical,

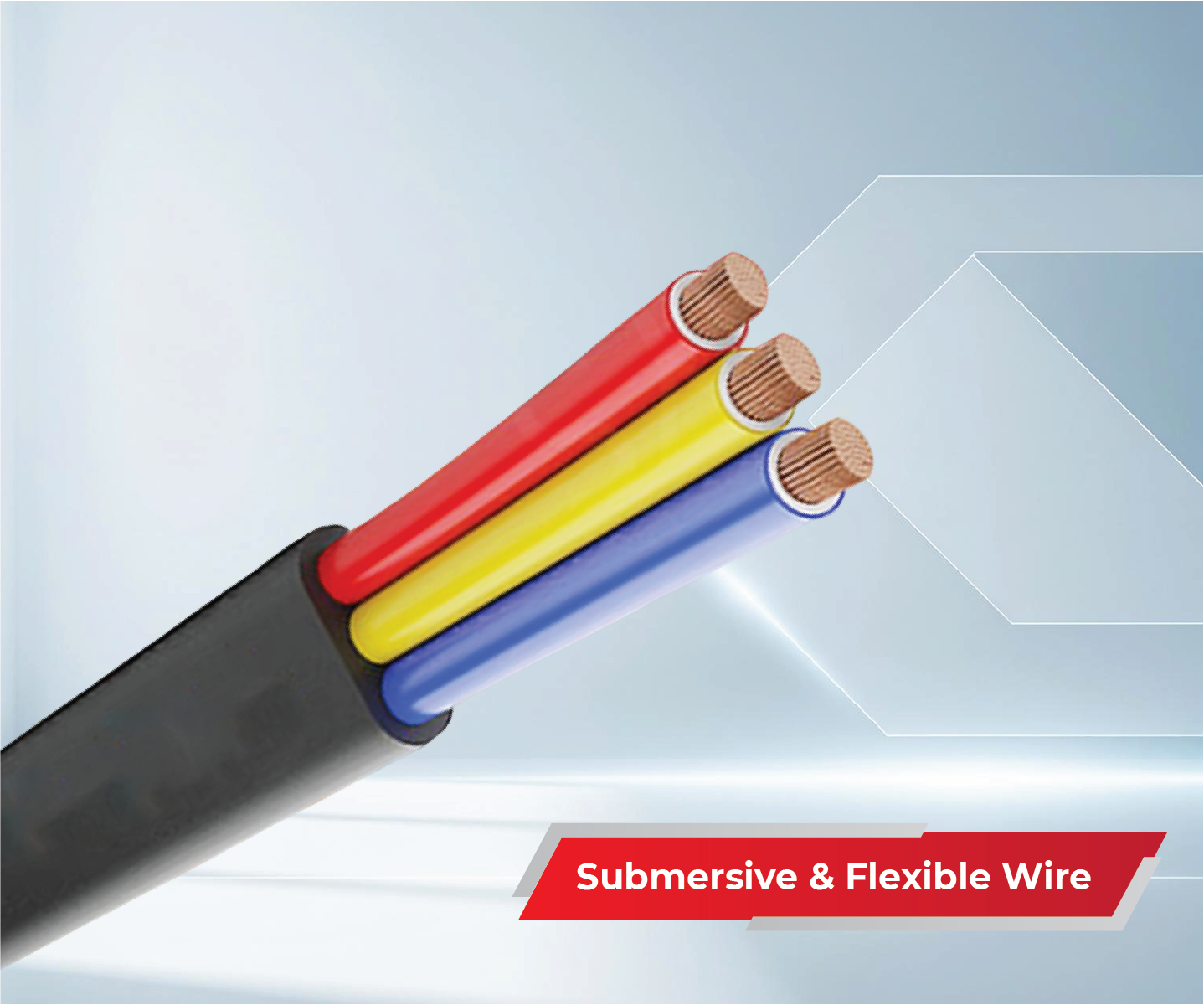

Home Submersible and flexible wire Description-Durable, cost-effective, and safe wiring solutions for homes, industries, and submersible applications.Made with high-quality PVC insulation for

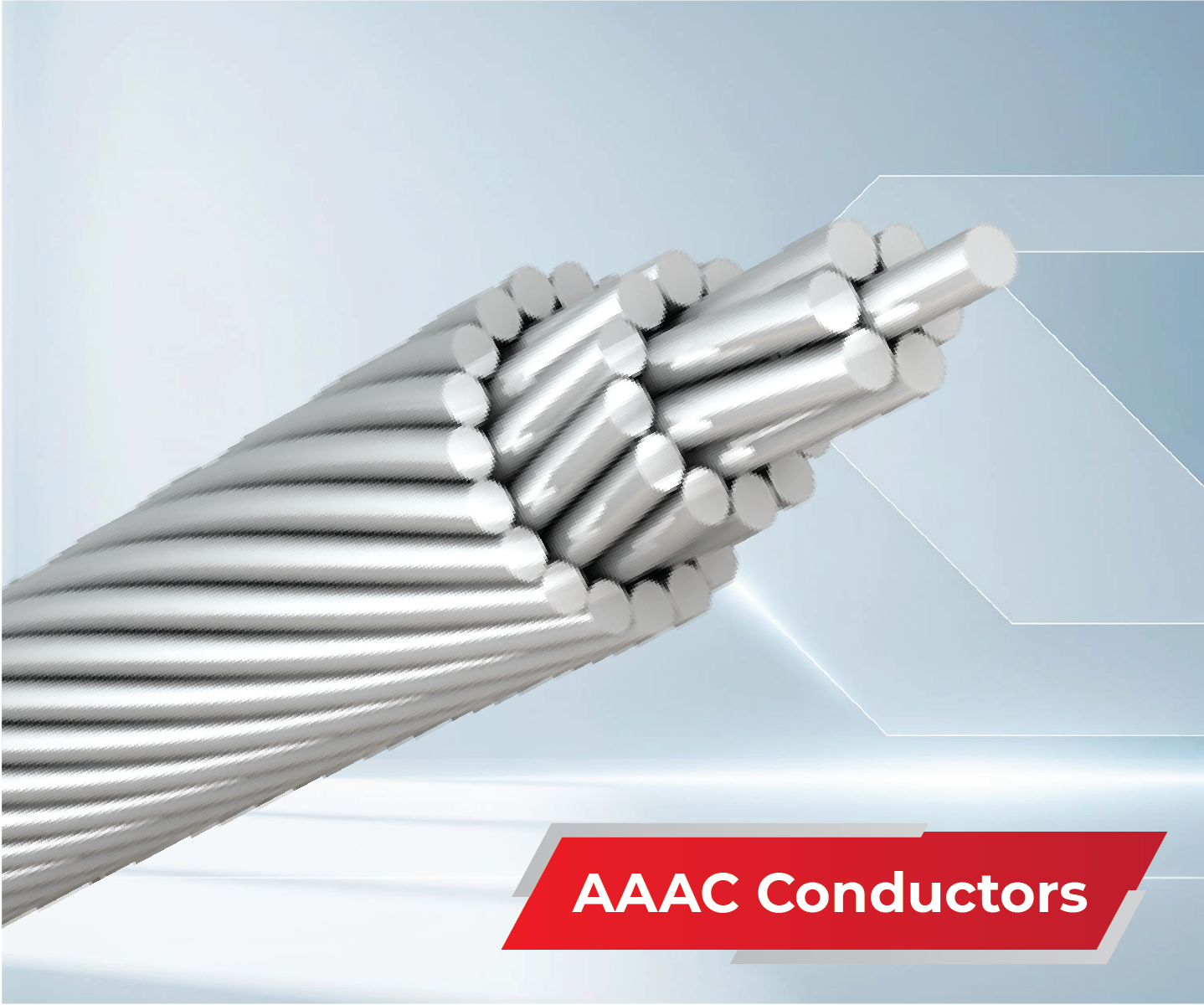

Home AAAC Conductors Applicable Standards & Certifications: BIS Licence No. CM/L-8400245413 Applicable Standard : IS: 398 Part-4 Description :- All Aluminium Alloy

Home ACSR Conductor Applicable Standards & Certifications :- BIS Licence No : CM/L-8400127912 Description :- PVC insulated cables, both armoured and unarmoured,

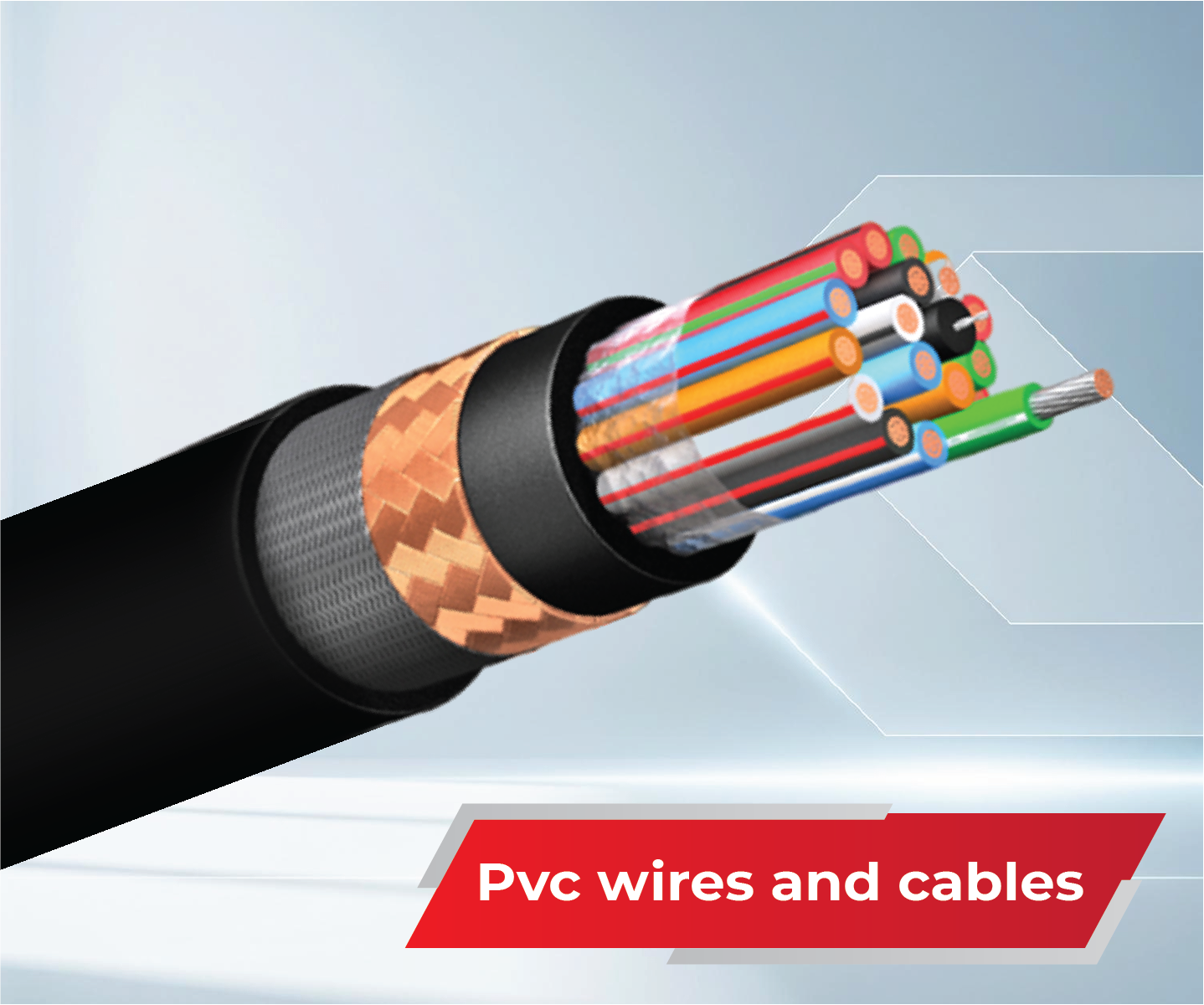

Home PVC Wires & Cables Description:- PVC cables are electrical cables that use Polyvinyl Chloride (PVC) as an insulation material. PVC is

Home Grade XLPE cables Applicable Standards & Certifications :- IS:7098 (Part I):1988 BIS Licence No.: CM/L-8400134210 Description :- XLPE insulated, PVC sheathed

Home Power and control cables Applicable Standards & Certifications :- IS:694 – PVC Insulated Cables IS:7098 (Part I) – XLPE Insulated Cables

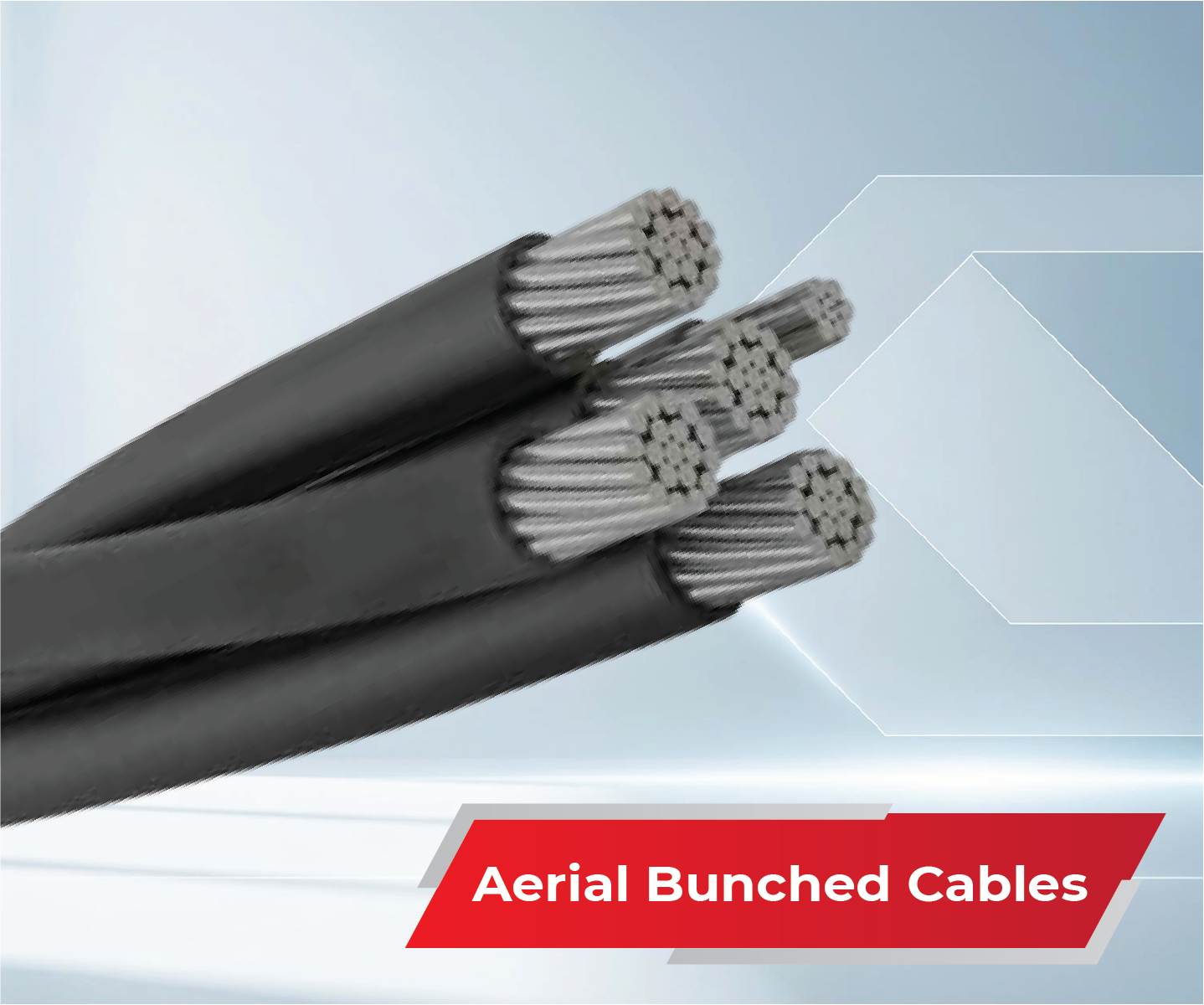

Home Aerial Bunched Cable Applicable Standards & Certifications :- BIS Licence No – CM/L-8400134210 CM/L-8400134210 For Certification Mark IS:14255 Description :- Aerial